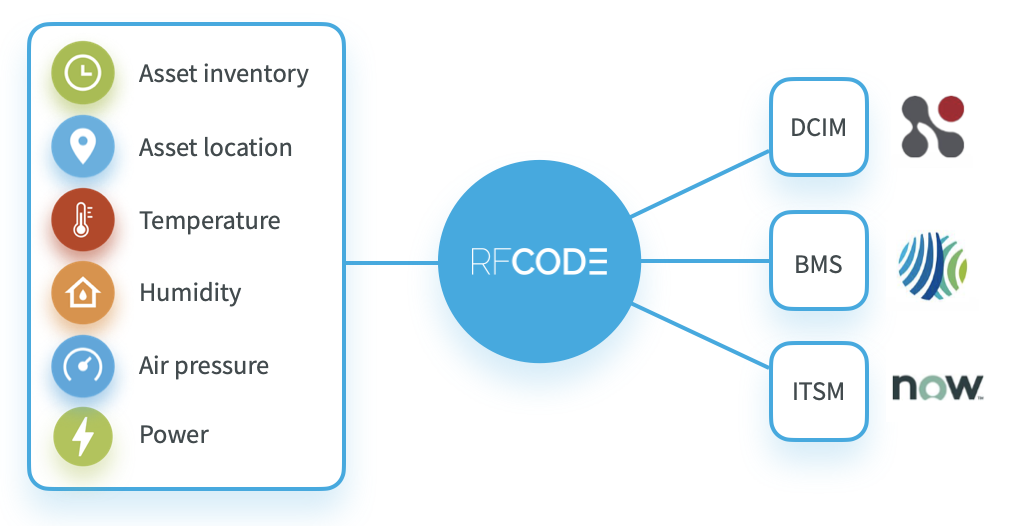

As useful as DCIMs are, they are dependent on accurate and real-time data. Without both, DCIMs can unknowingly report misleading asset location and environmental data. RF Code integration with off-the-shelf and homegrown DCIMs feeds these systems 100% accurate asset tracking and chain of custody data in real-time

RF Code’s proven DCIM integration automates two-way data synchronization so your DCIM is capturing and reporting on critical asset location and conditions. From loading docks to inventory and precise rack placement to decommissioning, your DCIM asset intelligence will empower you to make real-time decisions with confidence.

I don’t ever want to explain to my VP that an infrastructure management tool that we’re spending $100K a year on is not accurate enough.

By integrating your DCIM with RF Code, your organization will be able to replace error-prone, manually generated asset location data. Easy to install and configure, RF Code’s 100% asset tracking accuracy maximizes the investment in your DCIM by eliminating wasteful hard costs, mitigating risks, and freeing up limited resources.

Real outcomes reported by data center operators after integrating their DCIM with RF Code.

Eliminated manual audits and workflows.

Eliminated human errors.

Identified and remediated asset data discrepancies in the DCIM.

Ensured DCIM asset tracking data matches the reality on the floor.

Achieved precise asset location data down to the rack level in real-time.

Automates updates for newly arrived or removed assets in real time.

Maintained a complete location history of every tagged asset in the DCIM.

Improved financial accountability for assets.

Reduced dwell time and capital at rest inventory.

Boosted accuracy of capacity and spatial planning.

If you are interested in learning more about RF Code’s DCIM integration capabilities, discuss your unique use case needs, or maybe hear from one of our customers about their asset management outcomes, please fill out the form to schedule time with a product specialist.

Always ready IT asset inventory using active RFID technology eliminates costly, time-consuming, inaccurate audits performed with passive RFID, barcode scanners or spreadsheets.

99% asset tracking accuracy with automation across the entire lifecycle of every IT asset to minimize loss and dwell time.

Automated rack and server temperature monitoring prevents equipment from overheating and reduces overspending on energy.

Monitor relative humidity levels to ensure protection from corrosion and ESD (Electric Static Discharge).

Maintain air flow and pressure to ensure proper HVAC and CRAC performance.

Automated power consumption and capacity monitoring that delivers optimal power conditions and insights.