Data center asset management is easily transformed when you identify waste in the process.

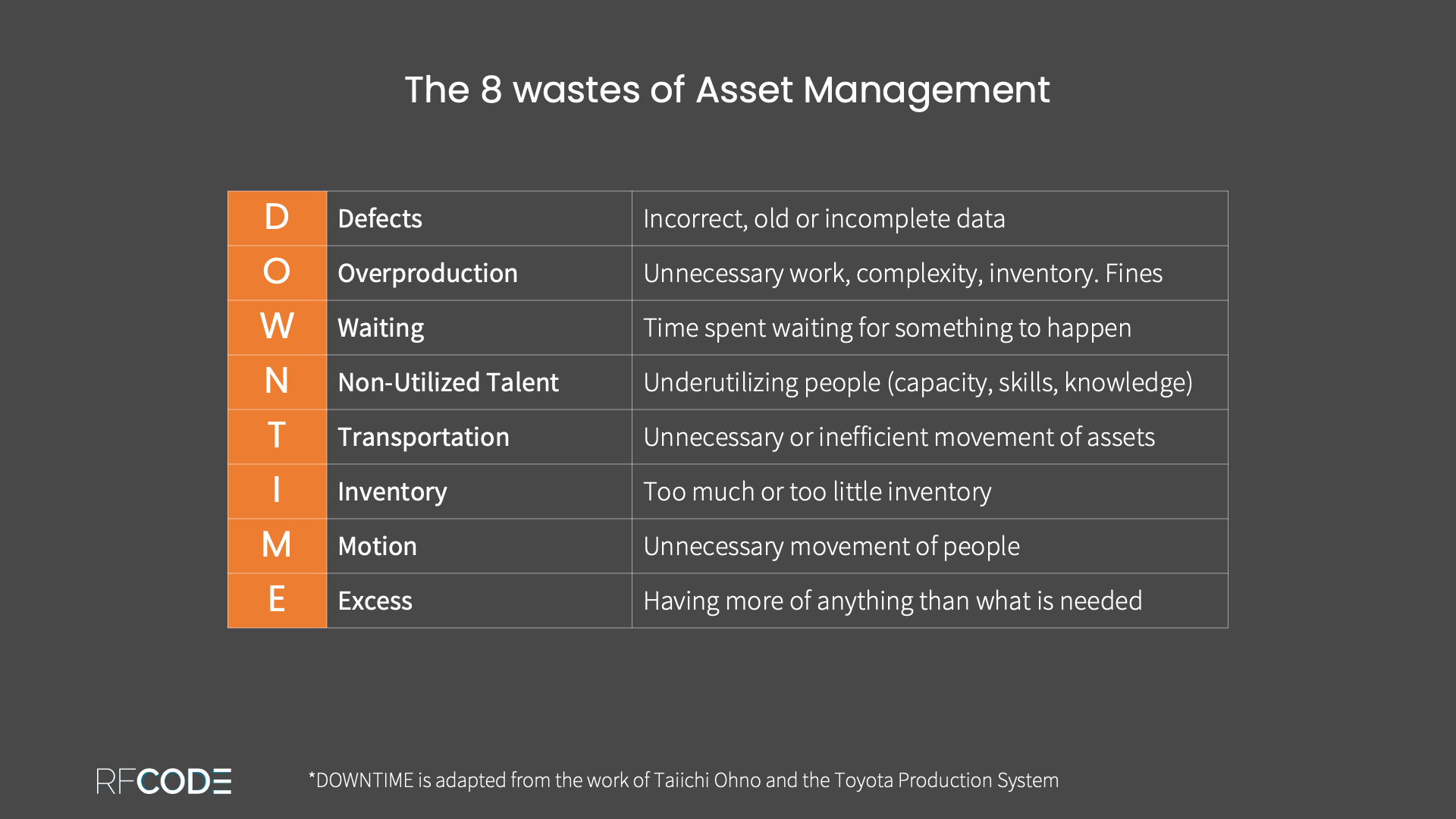

With the 8 wastes DOWNTIME framework adapted from the work of Taiichi Ohno and the Toyota Production System you can systematically – and surprisingly easily – diagnose the waste in data center asset management.

When applied to data center asset management the 8 wastes are:

Defects - Incorrect, old or incomplete data.

Overproduction - Unnecessary work, complexity, inventory. Fines, lawsuits.

Waiting - Time spent waiting for something to happen or be done.

Non-utilized Talent - Underutilizing people (capacity, skills, knowledge).

Transportation - Unnecessary or inefficient movement of assets.

Inventory - Too much or too little inventory.

Motion - Unnecessary movement of people.

Excess - Having more of anything than is needed.

Real world examples of waste include:

Defects - Assets not where they should be.

Overproduction - Manually auditing assets or verifying inventory.

Waiting - Waiting for audits to be done & errors to be fixed.

Non-utilized Talent – Manually counting, auditing, reporting assets.

Transportation – Assets sent to sites that don’t need them.

Inventory - High capital cost of inventory.

Motion - Time spent walking around data centers manually auding assets.

Excess – High capital cost of assets in storage.

Why identify waste?

For your people it could be higher productivity and job satisfaction (do the real value-add stuff that better utilizes skills and knowledge).

For your business it could be money – reduce the risk and impact of fines and lawsuits and get a better return on any capital or operational investments.

Increased performance; ability to scale to absorb growth...the list goes on.

Happy waste reduction.

Learn More